Ordering a Ready-to-Print screen with image

If you want to order a Ready-to-Print screen (with image on it), follow the 7 steps below to make ordering as easy as possible. Scroll down to see more ordering information.

READY TO PRINT SCREENS CAN BE ORDERED BY EMAIL ONLY.

- Frame size

- Mesh count

- Image - must in PDF format

- Stencil – tell us the type of ink you will be using

- Company name, phone number and address.

- Delivery – choose PICK UP or FEDEX

- Email above information to [email protected]

WE CANNOT PROCESS ORDERS UNLESS WE RECEIVE ALL THIS INFORMATION. YOU WILL RECEIVE AN ORDER CONFIRMATION WITH ALL COSTS FOR APPROVAL BEFORE WE PROCEED. READY TO PRINT SCREENS REQUIRE PREPAYMENT.

1. The Frame

We use only the O/D (Outside Measurement) for frame dimensions. All our frames are manufactured from aluminum.

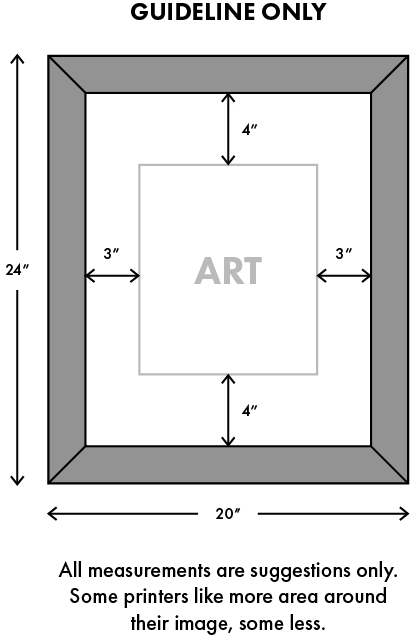

Once you have the size of your image, you can determine the size of the screen that you need. Typically, small format printers like garment printers, like to have at least 3 or 4 inches all the way around their image. You have to add on the frame profile to get the outside dimension. Refer to the Screentec Stock Screen chart for 6 sizes of frames that are READY to be stretched.

PLEASE NOTE: ‘Stock’ is referring to the frame only. We need time to stretch the screen. The stock screen sheet will give you pricing for the frame and the mesh that you select.

12” x 16” screen - suggested maximum art image size is 6.5” x 8.5” Art Image Area

14” x 20” screen - suggested maximum art image size is 8.5” x 15” Art Image Area

20” x 24” screen - suggested maximum art image size is 12” x 16” Art Image Area

22” x 26” screen - suggested maximum art image size is 14” x 18” Art Image Area

23” x 31” screen - suggested maximum art image size is 15” x 23” Art Image Area

25” x 36” screen - suggested maximum art image size is 17” x 28” Art Image Area

PLEASE NOTE: ‘Stock’ is referring to the frame only. We need time to stretch the screen. The stock screen sheet will give you pricing for the frame and the mesh that you select.

2. The Mesh

We stretch our frames using SEFAR mesh, which is in our opinion, the best quality mesh on the market. You need to know the mesh count that you want. Garment printers use anything from 60 mesh up to 305 mesh. Lower mesh counts hold less detail, and have larger openings allowing for more ink to pass through. Higher mesh counts hold more detail, and have smaller openings allowing for less ink to pass through. Refer to your ink data sheet, for mesh recommendations. Mesh is available in white or yellow and you need to give that information on order. The stock screen sheet will give you pricing for the frame and the mesh you select.

3. The Image

Generate your artwork as a vector image using Adobe Illustrator or Corel Draw. The image must be 100% size. Any fonts used must be included in the file or, the image must be converted to curves. Ink Jet film prices start at 25.00 per image/colour. Save as a .pdf file and email it to [email protected].

Adobe Photoshop files should be black and white. If the image is greyscale, you must provide a line tone. 45-55 line is suggested for Textile/Garment printers. Colour Separations (photographic films) can be done, and we will send you prices on request.

If you are printing more than one colour, please ensure there are registration or crop marks on the artwork, so we can center and register images on the frames. If your image needs to be placed in a location on the frame other than centred, please provide location drawing for correct set-up. If we don’t receive special set up instructions, the image will be centered.

4. The Stencil

PLEASE ADVISE IF YOU ARE USING WATER BASED INKS, as we need to use the type of emulsion required for that type of ink. The coat and shoot price is the same for either emulsion used. The price of a coat and shoot on any of our stock screens from 12” x 16” O/D up to 25” x 36” O/D is 45.00 each.

WE ARE HAPPY TO PROVIDE CUSTOM SIZED FRAMES MADE TO YOUR EXACT SPECIFICATIONS. PLEASE EMAIL US AT